Short Run and Long Run

Average Cost Curves:

Relationship and Difference:

Short Run Average Cost Curve:

In the

short run, the shape of the average total cost curve (ATC)

is U-shaped. The, short run

average cost curve

falls in the beginning, reaches a minimum and then begins to

rise. The reasons for the average cost to fall in the beginning

of production are that the fixed factors of a firm remain the

same. The change only takes place in the variable factors such

as raw material, labor, etc.

As the fixed cost gets distributed

over the output as production is expanded, the average cost,

therefore, begins to fall. When a firm fully utilizes its scale

of operation (plant size), the average cost is then at its

minimum. The firm is then operating to its optimum capacity. If

a firm in the short-run increases its level of output with the

same fixed plant; the economies of that scale of production

change into diseconomies and the average cost then begins to

rise sharply.

Long Run

Average Cost Curve:

In the

long run, all costs of a firm are variable. The factors of

production can be used in varying proportions to deal with an

increased output. The firm having time-period long enough can

build larger scale or type of plant to produce the anticipated

output. The shape of the long run average cost curve is

also U-shaped but is flatter that the short run curve as is

illustrated in the following diagram:

Diagram/Figure:

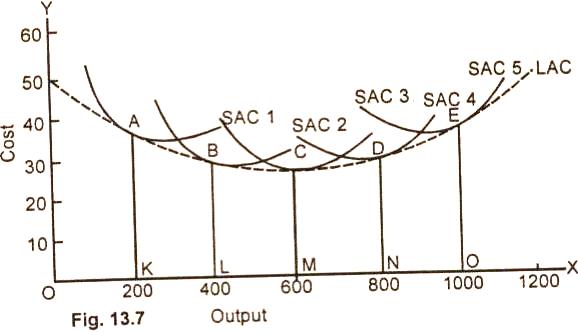

In the diagram 13.7 given above,

there are five alternative scales of plant SAC1 SAC2,

SAC3, SAC4 and, SAC5. In the

long run, the firm will operate the scale of plant which is most

profitable to it.

For example, if the anticipated rate of output

is 200 units per unit of time, the firm will choose the smallest

plant It will build the scale of plant given by SAC1

and operate it at point A. This is because of the fact that at

the output of 200 units, the cost per unit is lowest with the

plant size 1 which is the smallest of all the four plants. In

case, the volume of sales expands to 400, units, the size of the

plant will be increased and the desired output will be attained

by the scale of plant represented by SAC2 at point B,

If the anticipated output rate is 600 units, the firm will build

the size of plant given by SAC3 and operate it at

point C where the average cost is $26 and also the lowest The

optimum output of the firm is obtained at point C on the medium

size plant SAC3.

If the anticipated output rate is

1000 per unit of time the firm would build the scale of plant

given by SAC5 and operate it at point E. If we draw a

tangent to each of the short run cost curves, we get the long

average cost (LAC) curve. The LAC is U-shaped but is flatter

than tile short run cost curves. Mathematically expressed, the

long-run average cost curve is the envelope of the SAC curves.

In this figure 13.7, the long-run

average cost curve of the firm is lowest at point C. CM is the

minimum cost at which optimum output OM can be, obtained.

Relevant Articles:

|